BALL JOINTS

Ball Joints are necessary

- when points of application of force on the test specimen move on a plane or spatial (3-dimensional) path.

- when misalignments in the test setup cannot be avoided.

- in order to protect testing actuators against occurring transverse forces and bending moments.

The support shells are designed and assembled in such a way that the ball stud can be moved with zero-backlash and very little friction. Ball joints are therefore well suited for testing applications with tensile and compressive pulsating loading as well as reversed loading.

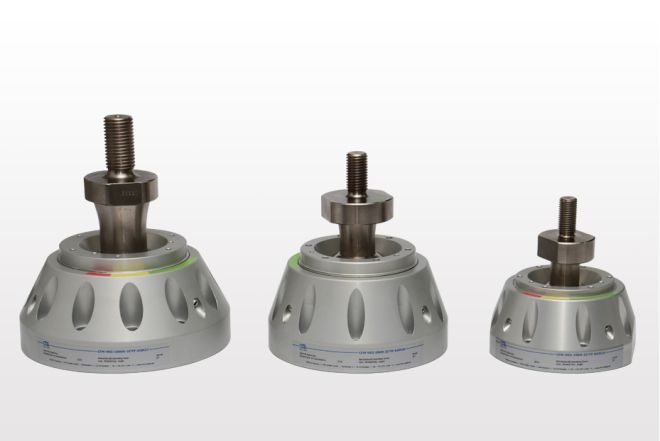

Design and function of the CFM Ball Joint with central thread

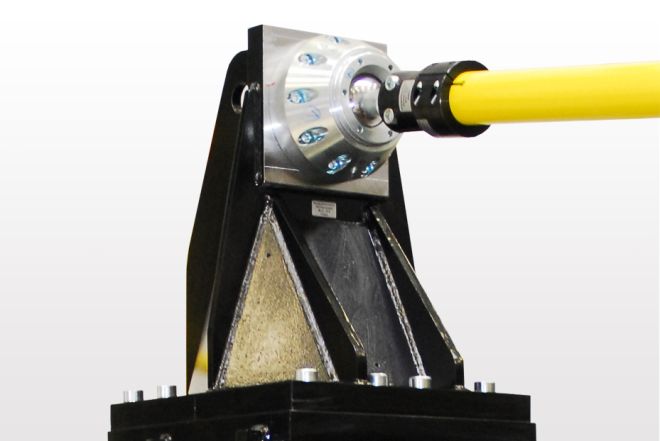

The ball joint comprises two coaxially assembled, coated support shells with an internal ball stud. The ball stud is composed of a sphere and a pin. It can swivel in all directions from the center position by an angle between 15° and 25° - depending on the type of ball joint. Adapter elements to the pin of the ball stud can be added for a coupling bar, the piston rod, or the actuator base at customer’s choice.

CFM Ball Joints are designed as low-maintenance components. Minimization of backlash between the ball stud and the support shells is realized by means of a central fine pitch thread. Occasional readjustment can be carried out easily. Zero-backlash has to be checked in regular intervals as stipulated in the operating manual.