PIT COVERS

CFM Pit Covers make the upper closure of a test rig and create a level passage between building and test rig. The portfolio of CFM Schiller comprises cover systems for seismic masses with clamping plates, 4/6/7-poster systems, chassis dynamometers, tilting test rigs, multi-axial shaker tables, and many more.

General Application

The pit cover consists of a substructure made from steel beams. This structure is generally anchored in the ground or walls of the pits. Alternatively, it can be designed with movable elements also. The substructure is covered with hot-dip galvanized diamond plates, which form a non-skid and impervious floor. Gratings can optionally be used as covers. Vibration-isolated clamping plates have a gap with relative motion. Special gap covers include additional rubber profiles which entirely seal the moving gap.

To ensure accessibility for employees and vehicles to the test rig, pit cover systems are offered as walk-on pit covers and optionally as drive-on pit covers. Standard loading capacities are 500, 1 000, and 2 000 kg/m2 respectively approx. 100, 200, 400 lb/ft².

The proven and cost-effective standard design for pit covers is customized by CFM Schiller according to your on-site conditions. We additionally offer special designs to utilize your working space to full capacity or to temporary enlarge it. These include for instance hydraulically or electrically folding covers, extendable telescopic covers, removable cover plates, or automatically controlled rollo covers.

4/6/7-Poster Systems

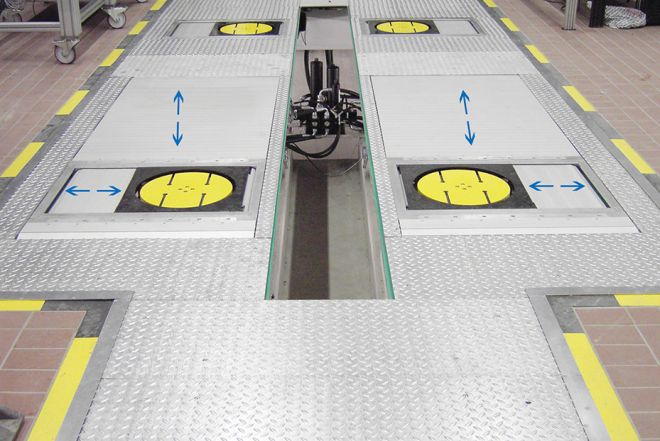

Poster systems, chassis dynamometers, or other test rigs that hold wheels of a vehicle have large open spaces around the wheel contact patches. These are supposed to be covered for safety reasons, among other things. CFM Pit Covers are particularly suitable for poster systems, whose actuators are traversed with X-Y positioning systems.

Outside the traversing paths of the actuators, the stationary standard pit cover system is used. Around the wheel pans, X and Y rollo covers are applied because they automatically move with the actuators. Their drives are activated by the control system of the corresponding X-Y positioning system. This ensures that no gaps occur in the pit cover when adjusting the wheel base (X) and track width (Y). A cost-effective alternative version offers removable inserts instead of automatic rollo covers. The inserts are sheets or hollow structural sections and have to be placed manually into the occurring gaps around the wheel pan.

Many applications require full accessibility to the underside of the vehicle. The CFM Center Walkway Rollo Cover provides entrance to the pit and the entire test rig components. They come in a single version (1 end-to-end cover) or a double version (1 cover from each end). It can be chosen between pulled and conveyed motion of the rollo cover.

The actuation of this rollo cover is also integrated in the control system of the corresponding positioning unit. A safety mechanism protects employees in the test rig against crushing hazards. The rollo cover automatically stops when mechanical contact is detected.

Environmental Chambers

CFM Schiller offers customized pit cover solutions for various test rigs that are operated in an environmental chamber.

For multi-axial shaker tables, the pit cover consists of folding stainless steel covers, which are moved by electric actuators with a lever system. The carrying frame is integrated either into the existent steel structure of the stationary pit cover or into the concrete walls.

For 6DOF road simulators that are operated in environmental chambers, CFM Schiller provides specially developed and manufactured poster systems including accessory components. Individual solutions with specially designed pans made of stainless steel, anodized aluminium structures, enclosures, and membranes ensure proper insulation of the test rig components against the climatic test chamber.

Noise Vibration Harshness (NVH)

Acoustic testing of noises, vibrations, and harshness (NVH) is carried out in soundproof testing rooms. In substructure of a test rig however, components like hydraulic actuators generate noises during testing.

CFM Schiller offers soundproof pit covers, acoustic enclosures for test rig components, and soundproof retrofitting of existent test rigs.

Cover plates for these special pit covers are shaped by means of laser or plasma cutting. These procedures ensure precise edges for a very exact assembly. The gaps between the cover plates are sealed with rubber isolation material. In order to absorb sounds as efficient as possible, acoustic panels (sound baffles) are installed underneath the pit cover.

Poster systems feature insulation bellows, which are installed between the actuator and the cover plates. Additionally, noises generated by the hydraulic actuators are isolated with special soundproof enclosures.