Foundations

Foundations for testing applications are made of concrete and steel. Masses of approx. 20 to 2 000 tons can be achieved. Heavy foundations on soft underground require additional pile foundations.

CFM Schiller plans and constructs the following types of foundations. There are basically two categories of foundations - vibratory and fixed foundations.

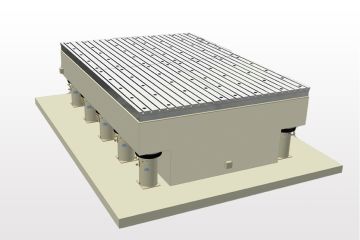

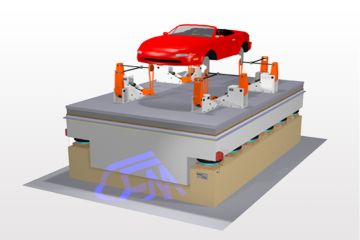

Seismic Masses

The foundation for most dynamic test rigs or other oscillating machines are vibration-isolated seismic masses. In combination with air springs or steel spring isolators, they prevent inertial forces or vibrations to be transmitted from the machine to the building or other sensitive machines. CFM Schiller carries out the entire development of the seismic masses including the plant planning and supply of further necessary components of the CFM Vibration Isolation Systems. We also offer turnkey solutions for your seismic mass projects.

We accompany you before and during the construction phase worldwide to ensure that the seismic masses are constructed properly according to the specifications. This service guarantees you the correct execution of construction works that are not ordinary for most contracting businesses. Our seismic masses are foundations that usually consist of a concrete body with integrated anchoring elements produced by CFM Schiller. High-strength anchors provide a dynamically fatigue rated connection of clamping plates, clamping rails, or base plates to the top of the foundation.

Experience and competence:

More than 1 500 installations worldwide.

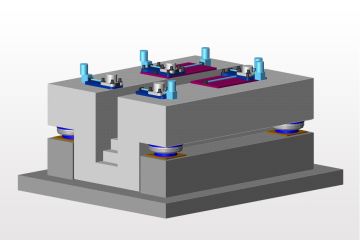

Prefabricated Foundations

Prefabricated foundations are small seismic masses as fully finished components made of concrete – with or without clamping plate. CFM Schiller manufactures prefabricated foundations with a maximum weight of 35 t and a width of up to 3000 mm.

Seismic masses as prefabricated components offer the following advantages:

- No construction activity or concrete works on your premises

- Short installation time onsite

- Integration of the anchoring system is carried out in-house at CFM Schiller. This is more cost-effective compared to doing so in your facilities

- No additional onsite curing time

- Can be transported to another location anytime - a major advantage in terms of flexibility

- Clean, smooth and cost-effective concrete surfaces thanks to system formwork

- Good damping properties

- Precise surface with high load-bearing capacity thanks to the cast iron or steel clamping plates or base plates

- The foundations are equipped with the necessary lifting eyes making it possible to easily transport them into your building