COMPONENTS FOR 4/6/7-POSTER SYSTEMS

Poster systems, also referred to as Hydropuls® systems, are generally laid out with 4, 6, or 7 servo-hydraulic actuators. They are the standard test rig for testing of vehicles as a whole, ranging from passenger cars to trucks to autonomous agricultural machinery.

CFM Schiller provides decades of experience in development and manufacture of the functional periphery for these test rigs. You will find the most important products and corresponding services on this site. Furthermore, we offer the necessary vibration isolation with air spring systems, acoustic insulations for servo-hydraulic actuators, and lifting mechanisms for vehicles.

Please feel free to contact us for further information.

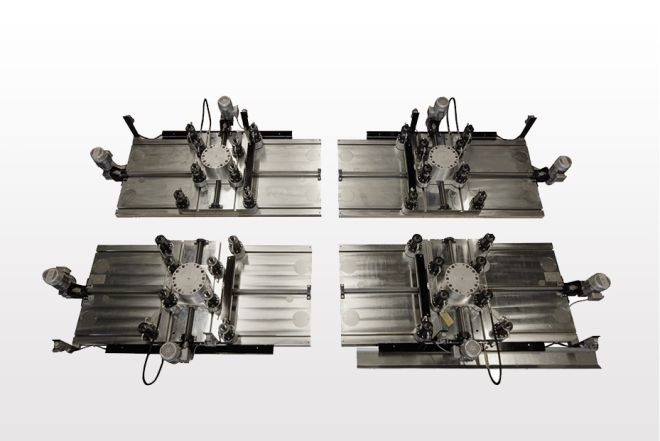

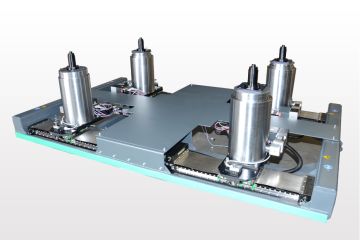

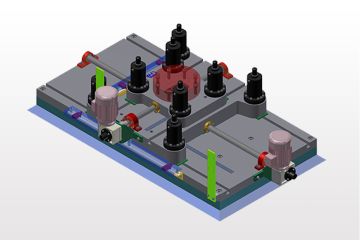

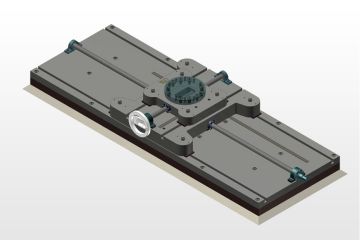

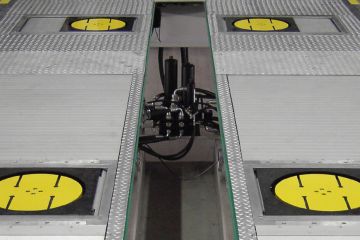

X-Y-Positioning Systems

Positioning systems from CFM Schiller allow manual or fully automated adjustment of axle track and wheel base for 4/6/7-poster systems or 6DOF road simulators.

The positioning system comprises the respective number of positioning units, each of which has a base plate connecting it to the ground or the seismic mass. Mounted on the base plate, two positioning plates carry out the movement in X and Y direction. Traversing is realized with spindle drives, which are driven by electric motors in the automated version. All plates that perform relative motion are clamped with spring clamping cylinders. The corresponding control system automatically clamps and releases the spring clamping cylinders. It also allows coupled or individual movement of the positioning units to adapt the posters to the axle track and wheel base of the specimen.

Customized designs regarding travel distances are possible with only little restrictions. For poster systems to be operated in environmental chambers, CFM Schiller offers positioning units with components made from stainless steel or with bronze coating.

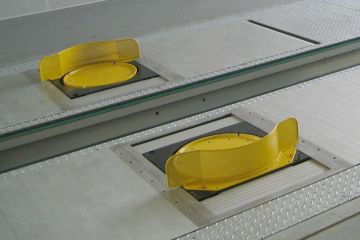

Wheel Pans

Wheel pans hold the individual wheels of the vehicle on various types of poster systems. They are available in round or rectangular versions. The wheel pan design is optimized in terms of stiffness, natural frequency, and weight. Their underside has the hole pattern which corresponds to the used actuators. Applications of the entire positioning systems in environmental chambers are possible. For this purpose, the surfaces of the wheel pans are hard anodized. To ensure safety regarding foot protection during operation, wheel pans are equipped with an aluminium skirt.

Pit Covers

All information about pit covers for 4/6/7-poster systems can be found here