Drop Tower Test Rigs

Test rigs for the execution of crash tests

Drop tower test rigs allow an analysis of work piece structures and materials regarding their deformation behavior. CFM Schiller has successfully designed and manufactured multiple drop tower test rigs. The specifications of the test rigs vary, depending on the customer’s requirements.

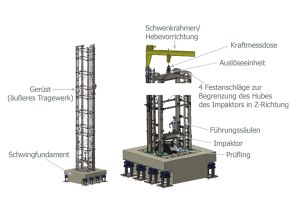

Drop tower test rig - 22 m / 72 ft

The distinctive feature of this test rig is the guided free fall, even in the impact zone. The framework of the drop tower is an approx. 22 m (72 ft) high steel structure with precision guiding. The impactor’s height of fall can be adjusted automatically over a range of more than 18 m (59 ft). Specimen up to 1.25 m (4.10 ft) in height can be tested with an application of force up to 1 MN in the moment of impact. The achievable maximum impact velocity is 56 km/h (34.8 mph).

Drop tower test rig - 15 m / 49 ft

for testing of stone damages on coated surfaces

The drop tower comprises an approx. 15 m (49 ft) high tube with an outer diameter of 323 mm (1.06 ft). Lifting and release mechanisms for the free fall are integrated at a particular position inside the tube. This test rig allows dropping samples with a maximum weight of 0.20 kg (0.44 lb) and maximum dimensions of 25 x 25 mm (0.98” x 0.98”). CFM Schiller provides system solutions for both the metrology and control technology.